Discover excellence in industrial HVAC with Advance Industrial Refrigeration's (AIR) latest innovation, the 120,000 CFM Make Up Air Unit (MUA). Crafted to thrive in even the most extreme conditions, this cutting-edge HVAC equipment showcases AIR's unwavering commitment to exceeding customer expectations. Engineered for remarkable performance across a temperature spectrum of 20ºF to 70ºF, our MUA redefines industrial air handling. From its meticulously designed components to seamless operation and innovative assembly process, the 120,000 CFM MUA sets new standards in efficiency and reliability. Step into the future of industrial HVAC – experience the exceptional capabilities of AIR.

Beyond social distancing...do you want to protect your team and customers from the Coronavirus?

AdsorbAIR pressurization units are designed to maintain a G1 reactivity level within corrosive rooms, as defined by ANSI/ISA Standard S71.04-2013. In addition to AdsorbAIR, RecircAIR recirculation units are recommended for spaces that have high traffic levels, very dusty environments, or are critical to overall plant operation. The addition of recirculation allows reduced recovery times for increased contaminant levels due to entry into the pressurized space. The activated carbon media oxidizes airborne contaminants, breaking them down to harmless components.

In these uncertain times, protecting team members and customers from exposure to the COVID-19 virus is a priority for us all. The CDC recommends the following “guidelines” for airborne infection isolation rooms:

Minimum of 12 air changes per hour

Filter recirculated air with HEPA (High-Efficiency Particulate Air) filtration – 99.97% efficiency @ 0.3 micron particle size

While conference rooms, control rooms, and lobbies are not medical isolation rooms, asymptomatic team members can release Coronavirus aerosol droplets that are extremely small and will remain airborne for a long duration. Room recirculation through HEPA filtration will remove these droplets, reducing airborne exposure duration and contamination on surfaces within the room.

Repurposing of our RecircAIR unit provides a cost effective option for Coronavirus protection. This requires temporarily mounting HEPA filter(s) within the carbon media section. Post-filters after the HEPA filter are not required. This provides protection for the following room volumes:

RecircAIR Model RCR-100

(1) Recirculation Fan rated for 1,000 cfm

12 air changes per hour for a total room volume of 5,000 cubic feet

RecircAIR Model RCR-200

(2) Recirculation Fans rated for 1,000 cfm each (2,000 cfm total)

12 air changes per hour for a total room volume of 10,000 cubic feet

Due to the MERV 8 and MERV 15 pre-filters, the HEPA filter will typically last for years and should not require replacement during this national health emergency. Once the threat of the Coronavirus has passed, the RecircAIR unit can then easily be repurposed to protect electrical spaces from corrosion related electronic failures by:

Relocating the RecircAIR unit to the protected electrical room

Removing the HEPA filter

Installing the carbon media modules and post-filters provided at the time of purchase

AIR is offering this as a cost effective solution to provide our customers with a means of protecting their team members with a product that also addresses their corrosion control needs in the future. A brochure of the RecircAIR unit is attached for your information. Contact us if you have any questions or would like more information.

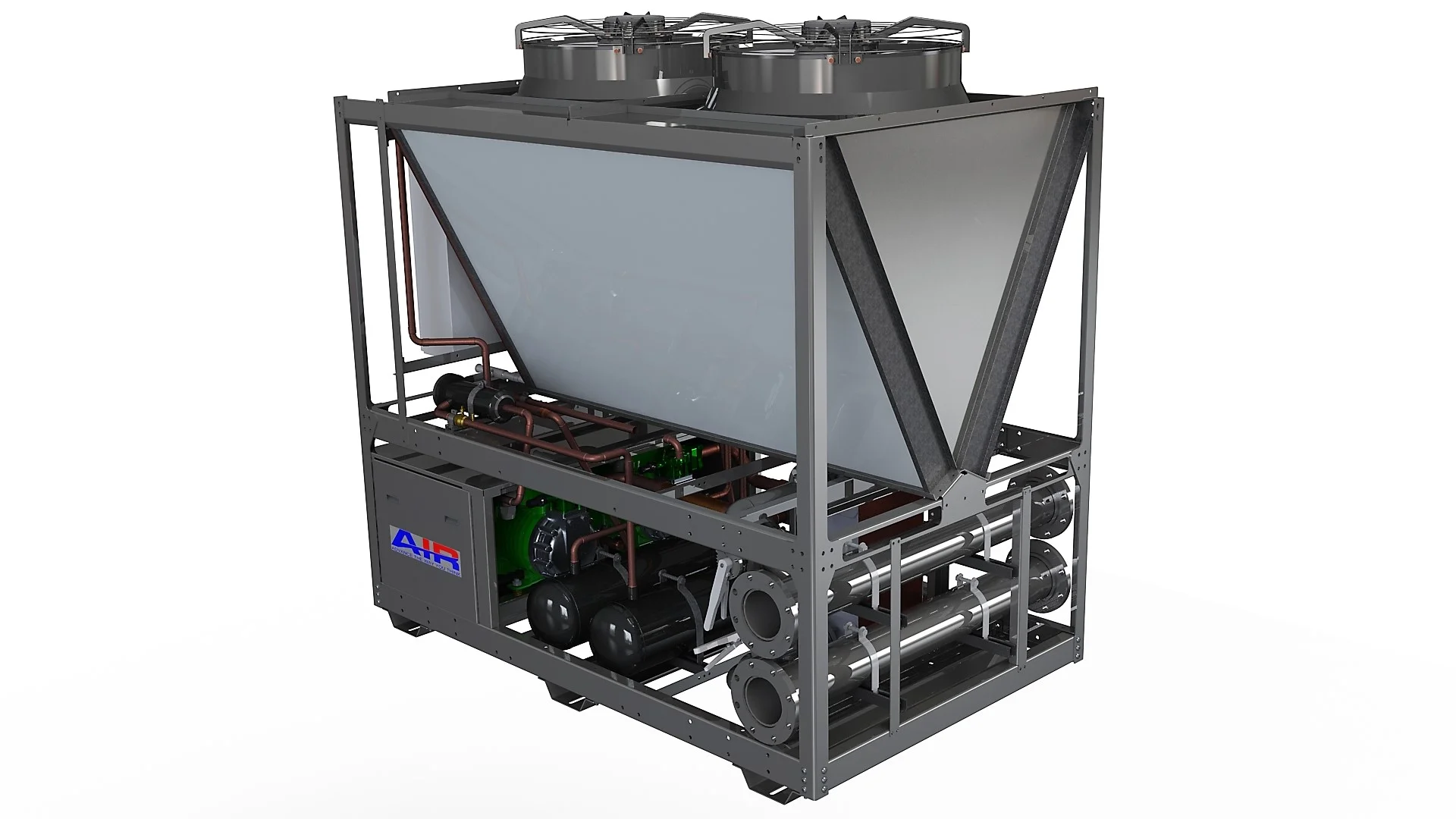

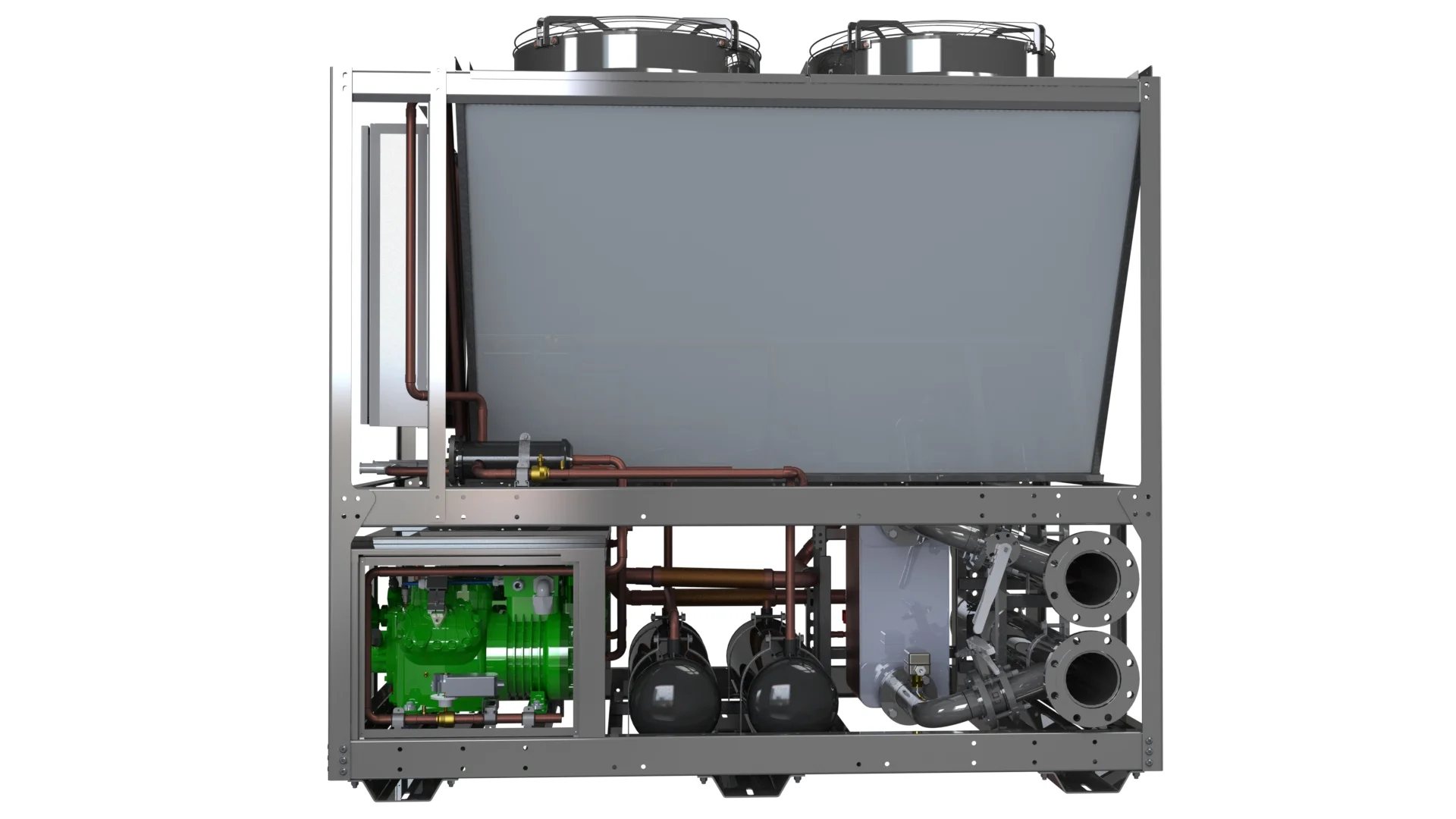

MODULAIR – AIR-COOLED MODULES NOW AVAILABLE!

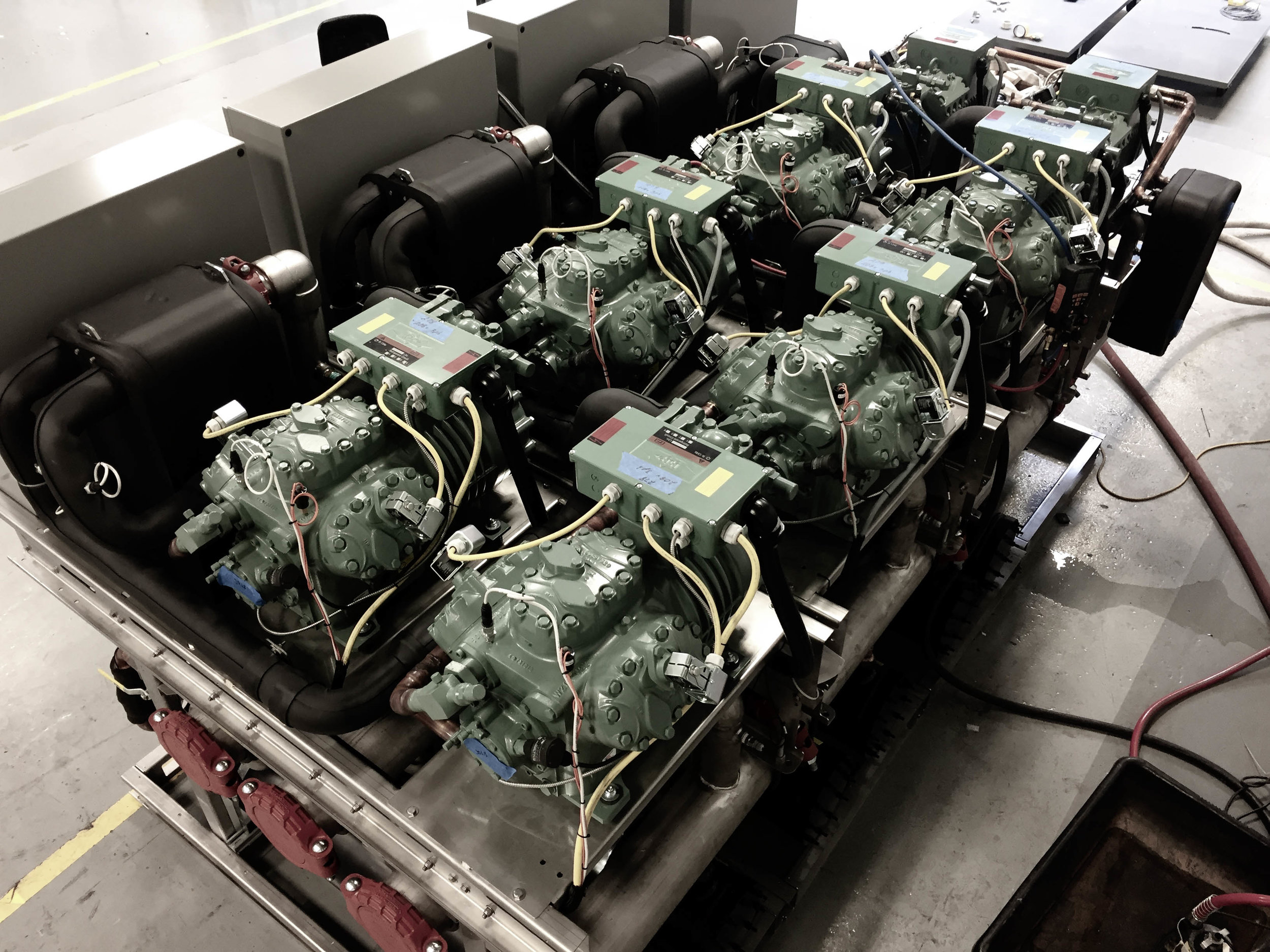

ModulAIR is a water chiller that brings robust serviceability and ASHRAE 90.1-2010 efficiency into a single compact package. Air-cooled chiller sizes are available in 5, 10, 15, 20, 30, and 40 tons. Each chiller can be used as a stand-alone unit or combined for installations up to 550 tons.

Building on the same premise of serviceability from its water-cooled brother, the new air-cooled modules feature an interconnecting stainless-steel header system. All refrigeration components can be replaced and serviced while the header remains in place. Compressors are isolated in a weather-proof enclosure ensuring compressor and electrical longevity. Optional insulation can be added to this enclosure for sound critical applications.

The air-cooled ModulAIR has many of the same features of the water-cooled version. For more information on the water-cooled model, click here. Air-cooled models are available with integral free-cooling coils. These coils work by bypassing the cooling water from the evaporator to a secondary coil located in the air-stream. The compressors are shut off and the condenser fans now cool this secondary coil. A built-in diverting valve automatically performs the switch-over. For cold climates, the chiller is available with low ambient controls which include; electronic head-pressure control valves, refrigerant liquid receivers, and heat tracing.

These chillers are available with R134a refrigerant for standard comfort cooling situations. They are also available with R507A refrigerant which is optimized for food processing, manufacturing and other low temperature applications. ModulAIR is a compact water chiller manufactured by Advance Industrial Refrigeration (AIR). For more information, visit the ModulAIR page.

INTRODUCING MODULAIR- A COMPACT WATER CHILLER WITHOUT COMPROMISE!

ModulAIR is a water cooled chiller that brings robust serviceability and ASHRAE 90.1-2010 efficiency into a single compact package. Chiller sizes are available in 8, 10, 12, 15, 21, 25, 41, 48 and 55 tons. Each chiller can be used as a stand-alone unit or combined for installations up to 550 tons. Chiller modules of any size can be mix and matched without limitation!

Unparalleled serviceability

Some users try to avoid modular chillers because traditionally they haven’t been as reliable as conventional chillers. ModulAIR brings all the robust features of a full size chiller into a compact foot-print. Fully cleanable shell & tube condensers and replaceable filter driers mean that customers no longer need to sacrifice reliability when a compact design is needed. Standard features such as compressor oil level and flow monitors show that this chiller takes reliability more seriously than the rest.

Unlike other modular chillers, ModulAIR is designed such that the condensers and evaporators can be serviced while the rest of the unit remains in operation. Unions on factory installed water piping can easily be removed to gain access to the front of the condensers for cleaning. The electrical control panels are hinged and rotate outwards allowing for easy access to the compressors. This means that service clearance is required from the front side of the chiller only, resulting in a smaller overall installation.

Smart control features

Smart controls are where this chiller differentiates itself from the rest. Each chiller module can run autonomously. The unique control algorithms are duplicated in each chiller module eliminating the need for any “master” controller. This removes a significant point of failure and improves redundancy for critical applications.

All ModulAIR chillers feature compressors with capacity control from 100% to 10% with advanced unloader technology. Operators no longer need to wonder at which point their chiller is the most efficient. The built in control sequence automatically determines how many compressors should be operational to deliver the lowest energy consumption possible. It doesn’t matter what the conditions might be, ModulAIR will automatically try different operational scenarios to determine which is the most efficient.

For applications where down-time is not acceptable, ModulAIR features a unique high head pressure avoidance sequence. This means the chiller will anticipate a high head pressure lockout situation and make every attempt to remain online during the most harsh conditions. If a cooling tower fan motor fails, or condenser water flow is restricted, the chiller will unload its compressors to take advantage of whatever heat rejection capacity remains available. Conventional chillers will simply continue to control to their chilled water set-point and end up tripping on high head pressure, remaining offline until the facility operator hits the re-set button.

Energy saving options

A wide variety of feature are available on the ModulAIR chiller for users who are concerned with energy efficiency. For systems that require variable primary flow, chillers are available with 2-way motorized valves. This allows the chiller to control to a constant return temperature while saving on chilled water pump energy. The condenser features a water regulating valve to properly control head pressure while reducing the amount of condenser water required in winter months.

Because of its modular design, other specialized accessory modules can be added to any system. A pre-engineered skid with pumps and tanks is available for a simplified installation. For water cooled systems, a free-cooling module is available which can take advantage of energy savings during winter months. This feature allows the chiller to save on compressor energy by using cold condenser water to cool the chilled water supply, rather than using mechanical cooling all year round.

ModulAIR can also help save energy in applications where cooling and heating is required at the same time. Condenser heat is wasted when it’s rejected outdoors. This can be used to satisfy heating requirements for domestic hot water, space heating, or other process heat loads. Unlike other small chillers that use high pressure refrigerants, ModulAIR uses a medium pressure refrigerant, allowing it to operate at higher discharge pressures more efficiently. This means that users can generate 175 F hot water from this chiller for all their hot water heating requirements!

For more information

ModulAIR is a compact water chiller manufactured by Advance Industrial Refrigeration (AIR). For more information, visit the ModulAIR page.